Some mis-conceptions about High & Low Pressure Water Mist Systems

Requires high purity water to avoid nozzle blockage

Not Correct: The system requires only potable water and has an integrated filter within the nozzle. Only stainless steel is used in all wetted parts for high pressure water mist systems.

High Pressure is dangerous to people

Not correct: Standby pressure for Hydrocore high pressure water mist systems is just 10bar, and only on activation does it reach 100+ bar. Low pressure water mist systems operate at much lower pressures.

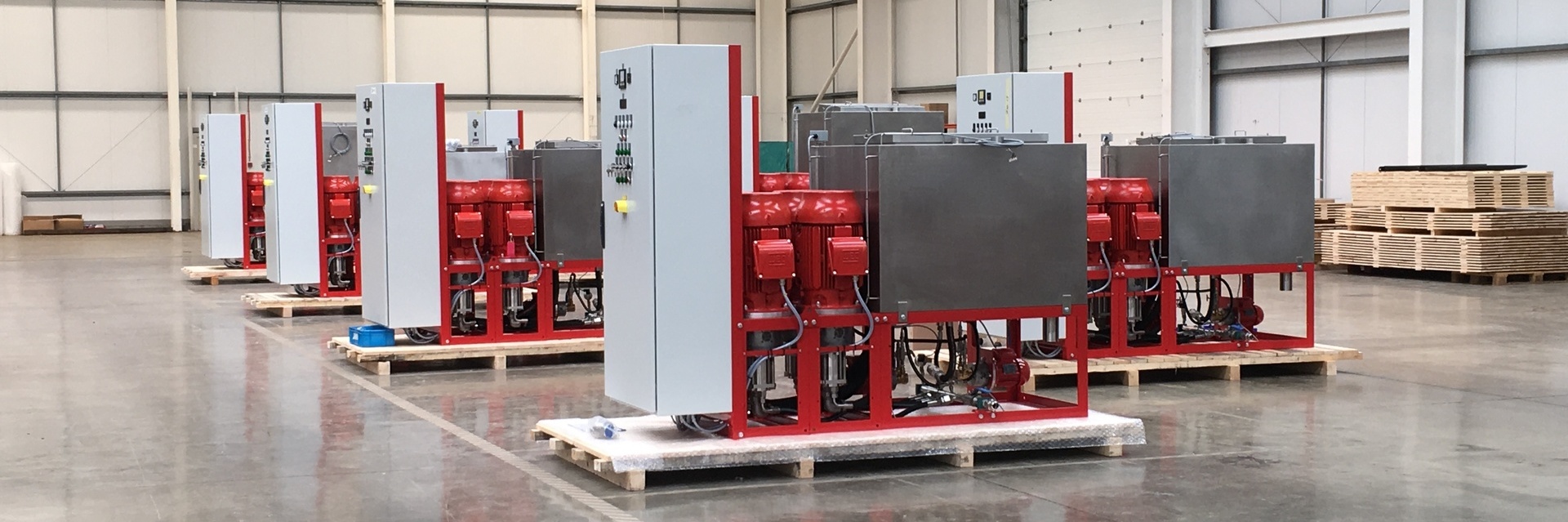

Requires complex installation layouts

Not correct: Layout is no more complex than for standard sprinkler systems and can be easily installed. Water Mist systems have a smaller footprint for the pump/tank assembly and require smaller tubing.

Limits visibility when deployed.

Not correct: Whilst any activation needs to be respected, it is merely deploying water mist.

Residual water remains after a Water Mist discharge

Not correct: The aftermath of a fire event is the soot particles that are left behind no matter which type of suppression system is used to bring the fire under control. Standard suppression systems would flood the room / zone with water and a lot of residual water is left behind which could damage the property. However, in case of a water mist activation, the residual water is far too less as compared to a standard sprinkler system as substantially less amount of water is required to suppress the fire and major